Achieving a lean state implies reaching industry best figures in KPIs of Quality, Costs, Productivity and Safety.

We developed a model that encompasses the principles, methods and instruments for perfecting processes, management system and manufacturing culture.

This model is based on the continuous improvement philosophy of Kaizen.

This model is based on the continuous improvement philosophy of Kaizen.

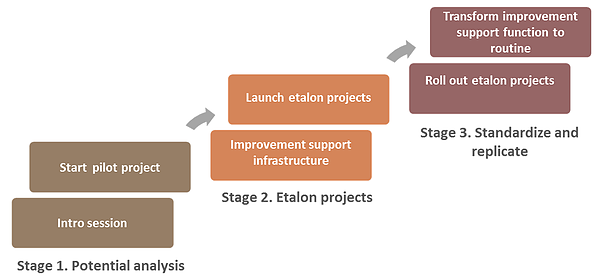

During the first stage we evaluate the improvement potential, create a project roadmap and improvement management structure. The company experiences its first Kaizen steps. The top managers are beginning to feel their commitment to lean production ideas.

At the second stage we select sample areas and introduce drastic improvements in them. During this stage we carry out a sequence of intensive sessions aiming at the fast investment return and fostering the spirit of excellence. At the second stage the focus shifts gradually from quick wins to emerging of a sustainable culture of continuous improvement. Sample areas, departments and processes serve as a boot camp for inner trainers and become examples for further replication of experience at the remaining departments.

At the third stage standardized solutions are replicated in all main and auxiliary processes, levels and branches. Ground effort is required to further the integration of the Kaizen process into sustained and regular organizational functions.

Send us your inquiry via e-mail or telephone us.